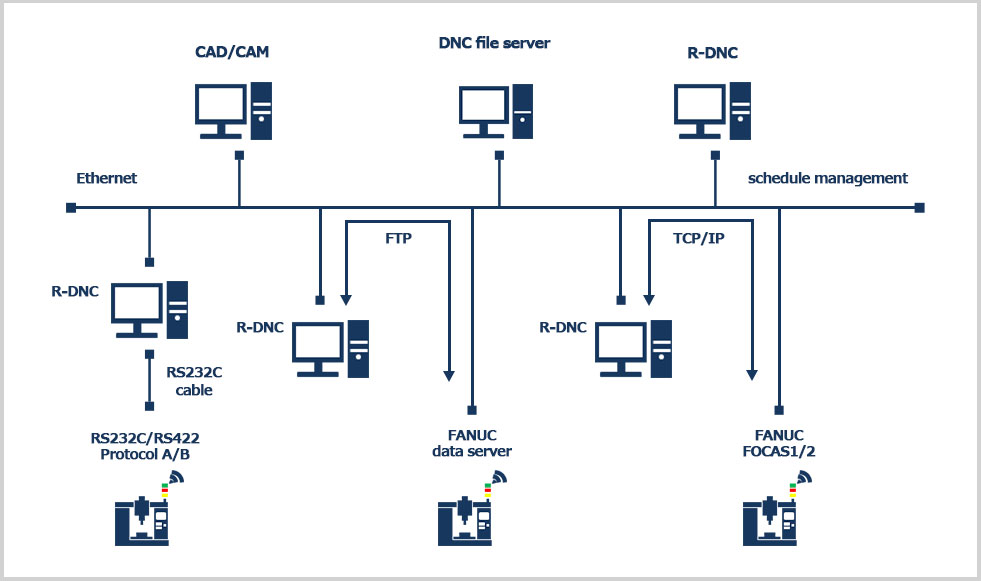

The NC program formulated by CAD/CAM is, via network, transmitted to CNC machine tools through RS-232C or RS422 interface, which is called client/server DNC system. Because FTP communication is also applicable, the program can be transmitted to data server (FTP server) of LAN specifications.

One computer can be used, via RS-232C interface (PCI applicable), to simultaneously transmit NC program to 10 CNC machine tools at most.

Besides the protocol B as transfer protocol, protocol A with FANUC/TOSNUC/OKUMA specifications can be used as well.

| function specifications | Various functions can help improve efficiency on production field! |

|---|---|

| transfer function | Download operation, schedule operation, continuous manufacture operation, integrated continuous manufacture operation and upload sub program (M98, CALL, G72, repeat, multiple 10) |

| NC data conversion | Unit conversion, decimal point conversion, scaling, mirror (X/Y/XY), coordinate rotation (90 degrees /180 degrees /270 degrees) text line conversion, multiple text line conversion, delete code, delete line |

| File management | file edit, delete, copy, rename, folder formulation, other applications linked |

| edit function | file edit, manufacture schedule edit |

| input manufacture condition | Work No., pallet No., tool No., rotating speed, conveying speed, length correction (address) diameter correction (address), tool correction data (G10), user-defined selections (10) |

| display transfer history | (100) |

| Transfer speed | 150, 300, 600, 1200, 2400, 4800, 9600, 19200, 38400 (RS232C/RS422converter is needed) |

| applicable data server | Applicable for the data server with FTP server made by FANUC company. |

* It can hardly be affected externally, and optical fiber solution is available.