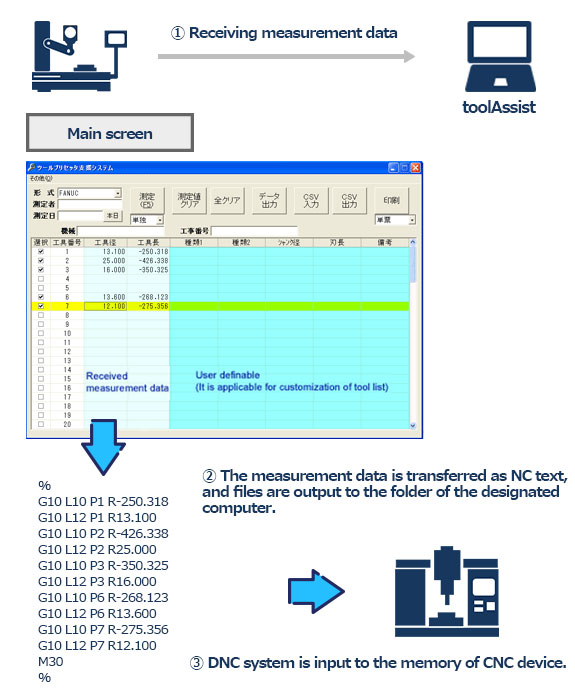

The correction data from “tool presetter” is saved, and “support software” of files are output as NC programs (G10).

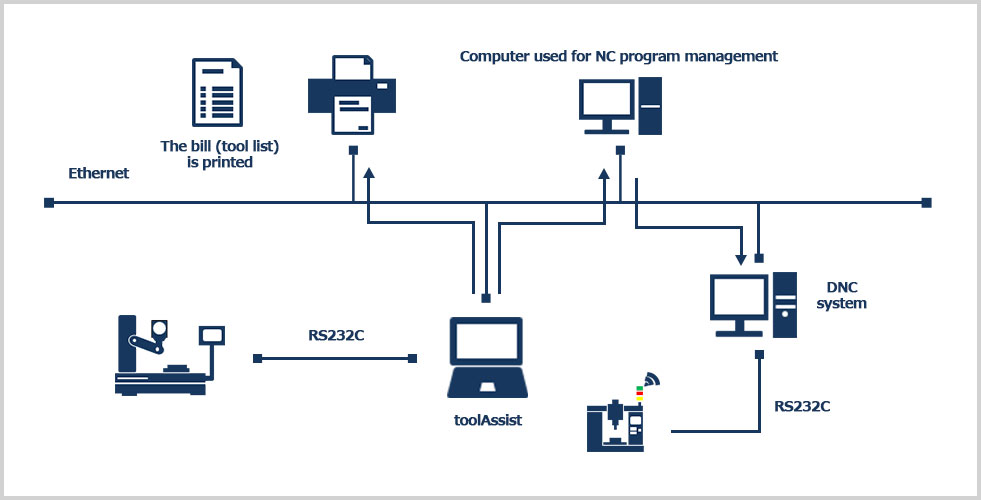

* The tool presetter is connected with the computer via RS-232C interface.

The variables are adopted to formulate measurement data formats of outputs (20 formats definable).

{usable variables list }

| #T-NO# | tool No |

|---|---|

| #X-DATA# | diameter correction |

| #Z-DATA# | length correction |

| #U1-DATA# | USER1 |

| #U2-DATA# | USER2 |

| #U3-DATA# | USER2 |

| #U4-DATA# | USER3 |

| #U5-DATA# | USER4 |