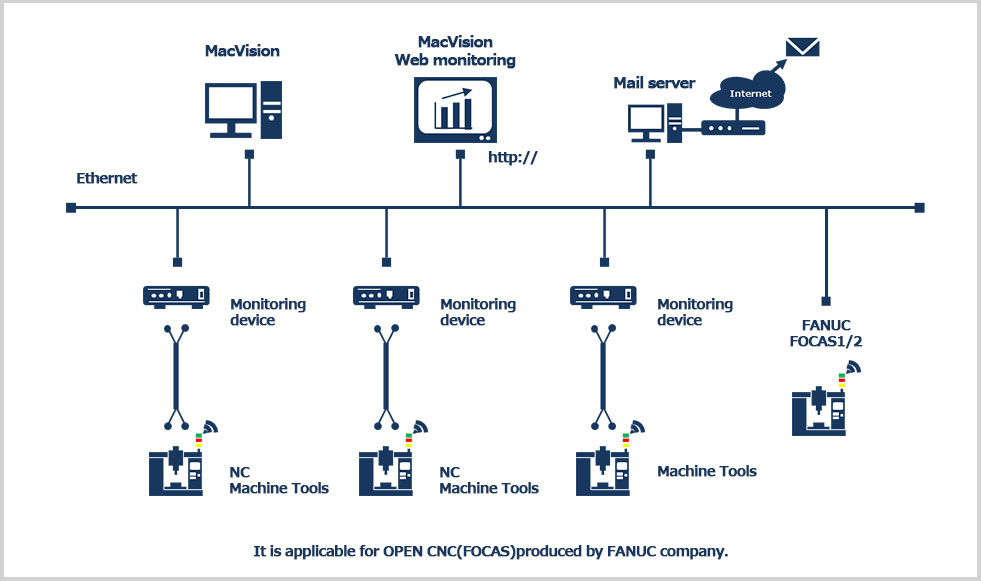

The operation data is automatically collected from CNC machine tools (Platlight signal shows alarming, finished, automatic operation,

etc.), and it is the software used for monitoring, notice, collection of operation results and management.

The operational efficiency is improved and cost is reduced.

The system aims to improve productivity.